Our shop is set up to manufacture jobs from large to small. Our fabrication areas consist of two 50’ x 175’ bays and one 50’ x 250’ bay. All our bays have a minimum height of 12’ under the crane hooks with the tallest bay being 14’ tall under the hook. With our fabrication facilities, additional paint bay, and warehouses, our facility totals over an acre under roof.

Details & Specs

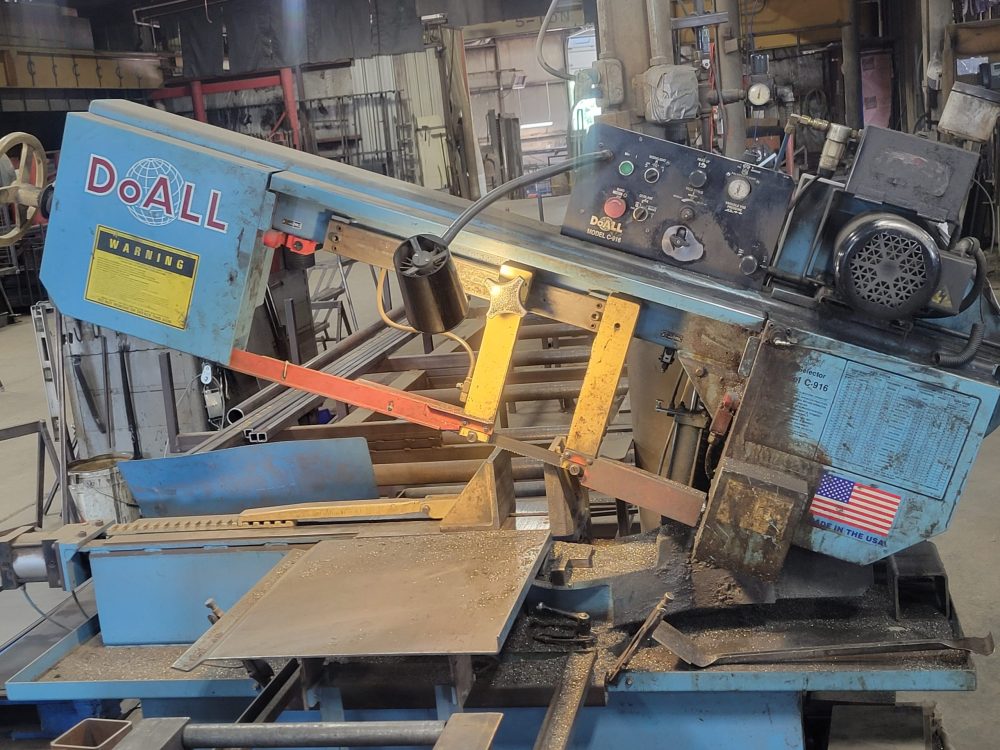

Our shop is equipped with DoAll C916 bandsaws. These bandsaws have a 9” x 16” cut capacity, Unist lube misters, and air vices.

Details & Specs

We view our Piranha ironworkers as versatile workhorses of the shop. They offer shearing, notching, hole punching, angle cutting, and bending in one compact machine. A variety of dies and tools can also be made or purchased for these machines such as tube benders, channel cutters, and sheet stamps.

Details & Specs

One of our largest pieces of equipment, our 200-ton hydraulic press brake has a 12’ bed. This press brake is entirely CNC controlled and offers repetitive part accuracy. Our dies include the following:

• 12’ long 4-way (V-openings of ¾”, 1”, 1.5”, & 2”) that can bend up to ¼” in thickness.

• 6’ long 4” V-die with a ½” thick capacity.

• Assorted gooseneck dies up to 1/8” capacity.

If an application requires specific dies, we are happy to acquire them.

Details & Specs

Our new 2021 CNC operated shear has a 13’ x ¼” thick cut capacity. This new shear is equipped with an adjustable thickness setting that allows us to cut thin material without curling the sheared edge while preventing blade wear on thicker material. The CNC software in this shear also allows us to program for multiple different cut lengths in order, as well as keep track of the number of pieces cut.

Details & Specs

In 2018 we refitted our entire facility with new multi-process welders. This gives us the flexibility to transition to different types of welding that best suit the job at hand. Our welders are all 100% duty-cycle allowing for uninterrupted use. All our feed heads save several weld settings allowing us to switch from welding thin sheet metal to thick structural steel without resetting our welders. Several of our welders also have dual feed-heads so we can switch to a different welding process at the push of a button.